Everything You Need to Know About Machines for Making Sachets

Release time: 2025-11-25

Table of Contents

In today’s fast-paced world, the demand for sachet packaging has soared across industries such as food and beverage, cosmetics, and pharmaceuticals. Whether you are packaging powdered drinks, skincare lotions, or condiments, sachets offer an efficient, convenient, and cost-effective solution for your business. To produce high-quality sachets, you need the right machine for the job. In this comprehensive guide, we’ll explore the different types of machines used to create sachets, the factors to consider when choosing the right one, and tips for optimizing your sachet production process.

What Is Sachet Packaging?

Sachet packaging refers to small, sealed bags typically used for single-serve products, either in powder, liquid, or granular form. Sachets are commonly used for items like sugar, coffee, ketchup, shampoo, and medical samples. The convenience of sachets has made them a preferred choice for both consumers and manufacturers, offering portability and easy use.

Types of Machines Used to Make Sachets

To produce sachets, various machines are available, each designed to handle specific types of products and production speeds. The choice of machine depends on the product being packaged and the production requirements. Below are the most common types of sachet-making machines.

1. Vertical Form Fill Seal (VFFS) Machines

Vertical Form Fill Seal (VFFS) machines are the most popular choice for producing sachets. These machines operate by forming bags from a roll of packaging film, filling them with the product, and sealing the bags. VFFS packaging machines are highly versatile and can handle a wide range of products, including powders, granules, and small solid items.

- Advantages:

- Versatility: Can package a variety of product types.

- Speed: Can achieve high-speed production, ideal for mass packaging.

- Compact Design: VFFS machines take up less space, making them ideal for smaller production lines.

- Ideal for: Powdered beverages, sugar, instant coffee, and seasoning.

2. Horizontal Form Fill Seal (HFFS) Machines

Horizontal Form Fill Seal (HFFS) machines are designed for producing sachets that need to be sealed on the sides. These machines create sachets horizontally, making them ideal for larger, bulkier products or products that require a side seal.

- Advantages:

- Precision: Ensures accurate sealing on the sides.

- Flexibility: Works well for both small and large products.

- Customizable: Can be adjusted for various bag sizes and packaging styles.

- Ideal for: Products that require a side-seal sachet, like bulk condiments or medical powders.

3. Stick Pack Machines

Stick pack machines are perfect for producing long, narrow sachets often used for single-serve items like sugar, coffee, and powdered beverages. The machine forms, fills, and seals a thin, rectangular sachet that fits comfortably in the user’s hand or pocket.

- Advantages:

- Ideal for single-serve products.

- Compact, easy-to-carry packaging.

- Efficient for products that need narrow packaging, such as coffee or tea.

- Ideal for: Coffee, sugar, salt, tea, and flavoring powders.

4. Pouching Machines

Pouching machines are a versatile option for creating sachets of various shapes and sizes. Unlike the more standardized VFFS or HFFS machines, pouching machines allow manufacturers to create unique, flexible packaging that suits a wide range of product needs.

- Advantages:

- Highly customizable packaging styles.

- Suitable for both liquid and solid products.

- Ability to create packaging in different shapes (e.g., stand-up pouches).

- Ideal for: Ready-to-eat meals, liquid food products, and lotions.

5. Liquid Sachet Filling Machines

When dealing with liquid products like sauces, oils, lotions, and beverages, a specialized liquid sachet filling machine is required. These machines are designed to handle liquid products, ensuring accurate filling and preventing leaks or spills.

- Advantages:

- Precise filling for liquid products.

- Prevents wastage or contamination.

- Can handle a range of viscosities, from thin liquids to thicker gels.

- Ideal for: Sauces, condiments, lotions, and other liquid-based products.

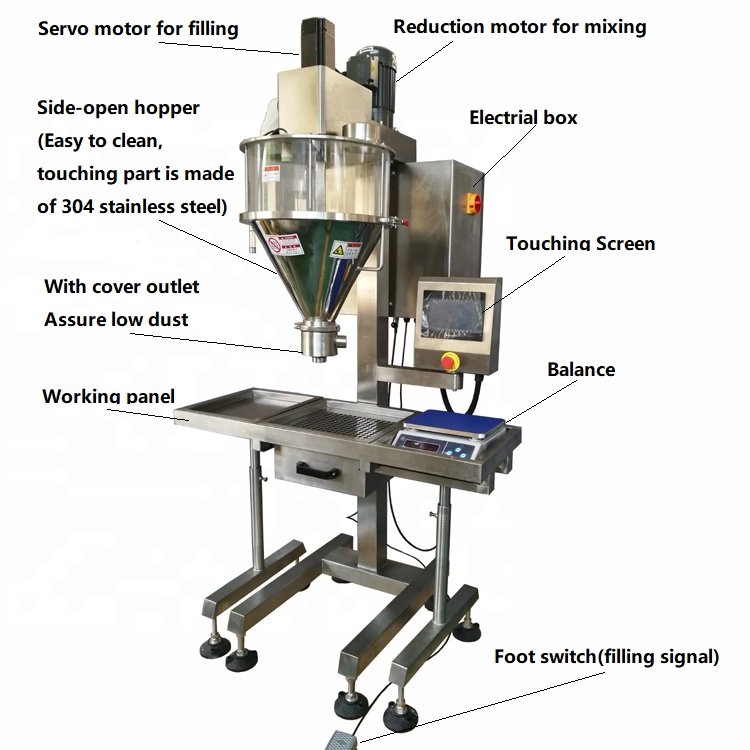

6. Powder Filling Machines

For packaging powdered products such as spices, baby formula, or detergent, a powder filling machine is essential. These machines are specifically designed to handle powders, ensuring they are filled accurately without spillage.

- Advantages:

- Handles powders effectively without causing clogging.

- Ensures precise measurement and accurate filling.

- Reduces product waste.

- Ideal for: Powdered drink mixes, detergent, spices, and other powdered products.

Considerations When Choosing a Sachet Making Machine

When selecting the right machine for your sachet packaging needs, there are several factors to consider:

1. Product Type

Ensure that the machine you choose is suitable for the type of product you are packaging. Liquid, powder, and solid products each require specific machinery to handle them effectively.

2. Production Speed and Capacity

Different machines offer varying speeds of production. Consider how many sachets you need to produce per day and choose a machine that can meet your capacity requirements.

3. Sealing Technology

The type of sealing technology is an important consideration. Some products require heat sealing, while others may need cold sealing. Ensure that the machine you select is capable of providing the right type of seal for your sachets.

4. Size and Dimensions

The size and dimensions of your sachets will determine the type of machine you need. Ensure that the machine can accommodate the dimensions of the sachets you want to produce, whether small, medium, or large.

5. Automation Level

You can choose between fully automatic, semi-automatic, or manual machines based on your production requirements. Fully automatic machines require minimal human intervention, while semi-automatic machines are more labor-intensive.

6. Budget and Maintenance

Consider the initial investment and ongoing maintenance costs of the machine. Some machines may have higher upfront costs but lower maintenance expenses in the long run. Evaluate your budget and choose a machine that offers the best balance between cost and functionality.

Finding the Best Machine for Your Sachet Packaging

The choice of machine for making sachets largely depends on the product you’re packaging, the desired production capacity, and the type of packaging you prefer. Whether you’re looking for a vertical form fill seal machine, a liquid sachet filling machine, or a stick pack machine, it’s essential to choose equipment that aligns with your business’s goals and production needs. By understanding your product’s characteristics and considering key factors like speed, sealing technology, and automation, you can make an informed decision and invest in a machine that will optimize your sachet production process.